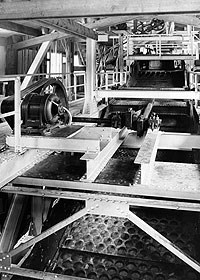

National Park Service This dynamic structure and bridge were the heart of the Blue Heron operation. The Blue Heron Tipple was modern and mechanized for its initial operation in the late 1930s. The Stearns Coal and Lumber Company publicized it as having cost a quarter of a million dollars at the "New No. 18 Mine, Blue Heron, Kentucky." A coal tipple separated the various sizes of coal coming from the mine in coal cars. These cars opened at the bottom to dump coal into a main 120-ton hopper leading to a 76-foot conveyor belt called an "apron feeder." Smaller sized coal traveled on to a series of shakers and screens which allowed coal of the right size through each screen down shoots or loading booms to coal cars below. Coal too large to be used domestically or commercially or to fit through one of the sizing screens, went into a crusher. The crushed coal then traveled back down the screens and on to the coal cars. Each screen selected out different size coal chunks, destined for different uses. Each of these sizes had a different name. There was block, egg, nut, stoker and the coal too small to fit a category was called "carbon coal" and was of little use. The Blue Heron Tipple could screen, separate and load over 400 tons of coal an hour. It is hard to imagine the intense noise and bustle of the coal tipple in those bygone years at Blue Heron. Today the operation is silent, but in the 1940’s and 1950’s there was an almost constant bedlam of activity as tram cars rolled up with their tons of raw coal. The mechanical clanging of the tipple, the noise of railroad cars, and the ever-present coal dust, produced a dynamic industrial environment.

To continue your visit through the Blue Heron Mining Community, choose the next "ghost structure" you wish to visit.

|

Last updated: June 23, 2018