Research Report

Gilpin's Falls Covered Bridge Documentation and Rehabilitation

by Jeremy Mauro

At the beginning of the 20th century there were more than 10,000 covered bridges in the United States. Currently approximately 800 remain.(1) While only a small percentage of the covered bridge stock survived the past century, collective knowledge of traditional wood bridge construction and repair has become nearly extinct. Through the coordinated efforts of the National Park Service's Historic American Engineering Record (HAER), the Federal Highway Administration (FHWA), the Maryland State Highway Administration, Maryland Historical Trust, and the Historical Society of Cecil County, the rehabilitation of Gilpin's Falls Bridge, located in North East, Maryland, succeeded in combining present-day preservation and documentation methods with techniques from the largely forgotten tradition of wood bridge construction.

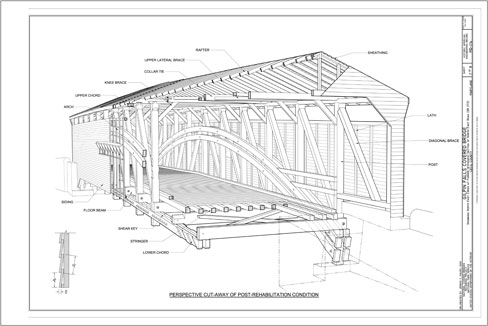

Built in 1860, Gilpin's Falls Covered Bridge spans North East Creek on Maryland Route 272, a regional road that connects Lancaster, Pennsylvania to the Chesapeake Bay at the port town of North East in Cecil County, Maryland. The Gilpin's Falls Bridge is one of six remaining covered bridges in Maryland and its 100-foot clear-span is the longest in the state. The bridge is an example of a Burr Arch Truss, a truss system patented in 1817 by Theodore Burr that combines a multiple king post truss with wood arches (Figure 1).(2)

The Gilpin's Falls Covered Bridge Committee, founded in the late 1980s by Earl Simmers, spent decades advocating for the bridge's preservation. In 2008, Cecil County was awarded a large grant from the FHWA National Historic Covered Bridge Preservation Program, making a rehabilitation project possible. The FHWA program was established to both "promote the rehabilitation, repair, and/or preservation of historic covered bridges" and also to fund the "research and education on and about historic covered bridges."(3) The Maryland State Highway Administration and the Maryland Historical Trust also contributed grants to fund the $1.4 million rehabilitation. The Historical Society of Cecil County contributed their largest grant to date of $8,000.(4)

With funding secured for the rehabilitation and study of Gilpin's Falls Covered Bridge, two projects were initiated in June 2009: the major rehabilitation of the damaged bridge and an intensive documentation of the bridge by HAER. The convergence of the rehabilitation by Barns and Bridges of New England and the HAER project, directed by Christopher H. Marston, HAER architect, created a unique opportunity to document covered bridge construction methods. Lead bridgewright Timothy Andrews had apprenticed under master bridgewright Arnold Graton Sr., and brought an exceptional knowledge of covered bridge construction to the repair project. The HAER team would return several times to record Andrews' techniques, in addition to completing standard HAER documentation. Two experienced timber framers, William Truax of Truax Timberwright Woodworks in New Hampshire and Jeremy Woodliff of New World Restoration in Wisconsin, assisted Andrews. During the yearlong rehabilitation, Andrews, Truax, and Woodliff resided in a farmhouse adjacent to the bridge and staged work activities in a large workshop on the property.

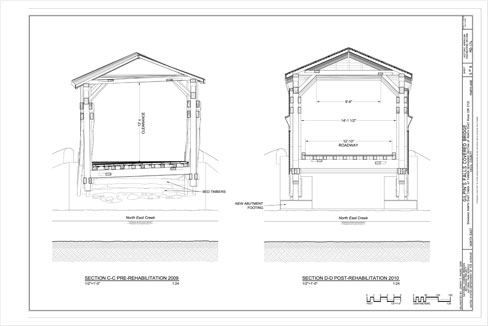

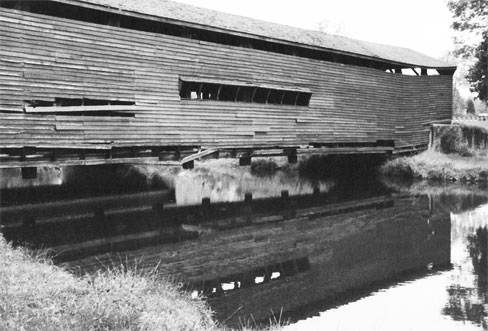

Recent flooding had caused structural failure of the bridge requiring immediate intervention, but more longstanding concerns of rot, insect infiltration, and inadequate maintenance and repair contributed to its decayed condition (Figure 2). The HAER team first documented the existing condition of the bridge at the start of repair work in June 2009.(5) Using a combination of high density laser scanning and hand measuring, the team recorded the sagging negative camber of the lower chord and floor, the bridge's deflection upstream, and the racking that occurred most severely at the north end (Figure 3).

|

Figure 2. View of the bridge before rehabilitation showing its sagging negative camber due to failures in the lower chord. (Photograph by Earl Simmers, 2005.) |

Understanding that the bridge was too fragile to be moved from the abutments for repair, structural engineers determined that rehabilitation work would take place while the bridge remained over the water, supported by a temporary steel platform. Working on the platform, Andrews, Truax, and Woodliff stabilized the bridge by jacking up the lower chord at each panel section and cross bracing the interior of the structure using chains (Figure 4). With the bridge stabilized, they began the process of aligning the bridge using a clamping system that gathered back the failures in the lower chord and also installed stacks of corbelled supports, or falsework, that returned the truss to its proper geometry (Figure 5).

|

Figure 4. Will Truax (left) and Jeremy Woodliff (right) tighten cross bracing as a technique to correct the upstream bow, also known as lateral deflection. The bridge deflected when failures in the lower chord increased the load carried by the arches, causing them to deform. (Photograph by author.) |

|

Figure 5. This view shows two temporary support systems, corbelled falsework and cross-chaining, that Andrews used to shore up the trusses and coax them back into their correct alignments. A temporary steel platform spanned the creek and carried the weight of the bridge during the rehabilitation. (Photograph by author.) |

Within the larger process of stabilization and alignment, Truax and Woodliff practiced detailed craftsmanship that relied heavily on traditional hand tools. The strength of complex connections between truss members, made from Eastern White Pine, depends on tight fitting joints held in place by treenails made from Black Locust. Copper Napthenate was brushed onto mating surfaces before assembly to discourage decay.

Although it is somewhat common to reinforce covered bridges with steel beams or other modern materials, Andrews resisted using any engineering technology that was not available at the time of the bridge's original construction. Andrews' confidence in the strength of the bridge's wood truss did not preclude him from making small period appropriate improvements such as doubling the length of shear keys, creating channels for debris to be swept away, and designing more stout abutments that defended against rot by allowing air circulation around the ends of the arches.

The overlapping of the HAER documentation project with rehabilitation at Gilpin's Falls Covered Bridge resulted in a set of drawings that show both the pre- and post-rehabilitation state of the bridge, and includes illustrations of techniques used during the repair process. The documentation project fulfilled HAER's goal of documenting significant U.S. engineering works and also examining historic processes. In addition to public outreach through the HAER collection at the Library of Congress, this project was presented at the 2010 Preserving the Historic Road Conference and will serve as a case study in a forthcoming FHWA publication on rehabilitating covered bridges to the Secretary of the Interior's Standards for the Treatment of Historic Properties.

About the Author

Jeremy Mauro is an architect with the Historic American Engineering Record of the National Park Service, based in Washington, DC.

Notes

1. Dan Brock, William S. Caswell, and David W. Wright, World Guide to Covered Bridges (Hillsboro, NH: National Society for the Preservation of Covered Bridges, 2009), lxii.

2. Emory L. Kemp, American Bridge Patents: The First Century (Morgantown, WV: West Virginia University Press, 2005), 14.

3. M. Myint Lwin, "National Historic Covered Bridge Preservation Program Request for FY 2010 Grant Applications," Memorandum, U.S. Department of Transportation, Federal Highway Administration, http://www.fhwa.gov/bridge/nhcbp/100503.cfm, May 5, 2010, accessed on January 5, 2011.

4. Wallace, Montgomery, and Associates, LLP acted as the project engineer, Kinsley Construction Company was the general contractor, and Barns and Bridges of New England was the timber framing subcontractor.

5. The documentation was completed by field supervisor Anne E. Kidd, summer architect interns Bradley M. Rowley, Jeremy T. Mauro, and Csaba Bartha, Romania (who was hired through a partnership with the International Council on Monuments and Sites [ICOMOS]), under the direction of Christopher H. Marston, HAER project leader. Lola Bennett wrote the history, and David Ames produced the large format photography.