NASA

Large tailings dams, which are built to contain mining waste and are among the largest dams and structures in the world, must stand in perpetuity. Experience shows that a catastrophic release of tailings can lead to long-term environmental damage with huge cleanup costs. The failure rate of tailings dams is also significantly higher than that of water supply reservoir dams. The difference probably reflects two factors: (1) the ability to use construction types for tailings dams that are more susceptible to failure, and (2) the fact that tailings dams are most often constructed in sequential “lifts” over several years, making quality control more challenging than for water supply dams that are

constructed all at once. There is a well understood tendency to make assumptions that favor short-term economic situations, and to assume that present technology can and will minimize the long-term risks associated with the design, operation, and long-term closure of tailings facilities. Technology and science have limits, and care must be exercised not to allow the significant economic incentives associated with present day decisions about risk to bias our estimates of the magnitude of these risks to be less, rather than more, conservative.

<br><br>

NASA

Tailings Dam Failure Incidents

Engineered tailings impoundments have been around for about a century (MMSD 2002). The construction and care of a tailings dam is a relatively new phenomenon to society and to mining, which historically disposed of its waste in the most advantageous way, including piling wastes adjacent to the mines and discharging into nearby water bodies. There are more than 3,500 tailings dams located around the world (Davies 2002) and between 25,420 and 48,000 large water supply dams worldwide (WCOLD 2000). Yet tailings dam failures (events resulting in the escape of tailings and/or water from the tailings dam) have occurred more frequently than water supply dam failures. Even with the obvious requirement for long-term stability, the number of tailings dam failures since 1970 has significantly exceeded the failures for dams used for water supply (UNEP 1998).

A catastrophic tailings dam failure can have significant financial and environmental consequences—financial from cleanup and environmental from metals contamination to surface and ground waters, and to soils.

NPS Image

The scale of such consequences is demonstrated by the tailings dam failure at Los Frailes, near Seville, Spain. The dam failure in April 1998 released approximately 528 million gallons (2 million cubic meters) of pyrite sludge and another 1 billion gallons (4 million cubic meters) of acid water containing high concentrations of heavy metals (zinc, lead, arsenic, copper, antimony, thallium, and cadmium) into the Guadiamar River. A 38.5-mile (62-kilometer) -long section of the river, ranging from 0.3 to 0.6 miles (500 to 1,000 meters) in width, was affected. Of the area affected by the accident, 6,560 acres (2,656 hectares) were part of the Doñana Nature Park and 242 acres (98 hectares) were within Doñana National Park. Cleanup costs were in excess of $225 million (€215 million at the 2002 conversion rate) (Arenas and Méndez 2002).

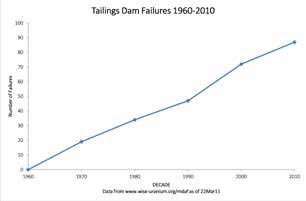

Because of the alarmingly high number of tailings dam failures, the International Commission on Large Dams (ICOLD) convened several studies to investigate tailings dam failures (ICOLD 2001). In the 10 years since the ICOLD 2001 report, the failure rate of tailings dams has remained at roughly one failure every eight months, or about three failures every two years (Figure 2). Over a 10,000-year lifespan (a figure often used for how long these structures will need to maintain their integrity) (Wieland 2001) this implies a significant and disproportionate chance of failure for a tailings dam. One explanation might be the residual effects of outmoded designs and construction practices, but it has been 15 years since the International Commission on Large Dams initiated a major effort to investigate tailings dams and change construction and operational practices, and the rate of tailings dam failures has remained relatively constant.

Tibor Kocsis

These dam failures are not limited to old technology or to countries with scant regulation. Previous research indicates that most tailings dam failures occur at operating mines and 39 percent of such failures worldwide occur in the United States, significantly more than in any other country (Rico 2008).

Tailings Dam Construction Types

Tailings dams differ from water supply reservoir dams in two significant ways—dam-life design, and dam-construction design.

First, unlike a dam built for impounding water, which can ultimately be drained if the structural integrity becomes questionable, a tailings dam must be designed to safely impound the material behind the dam in perpetuity. This consideration should entail additional design requirements, especially with regard to the seismic and hydrologic events the dam might experience.

World Information Service on Energy Uranium Project

Tailings dams are not designed to be free draining after facility closure. For potentially acid-generating tailings it is usually the objective to keep this material saturated after mine closure, because saturation is the best way to limit oxygen and minimize the acid-generation process.

Even if tailings dams were designed to be free draining, it is likely there would be some residual level of saturation (the phreatic level) in the tailings because of their fine composition and low permeability. The residual phreatic level would likely mean the lowest level of tailings would remain saturated. Should the dam fail due to a large seismic event, liquefaction of the lowest level of tailings would probably lead to a large tailings release through a ruptured dam.

EcoFlight

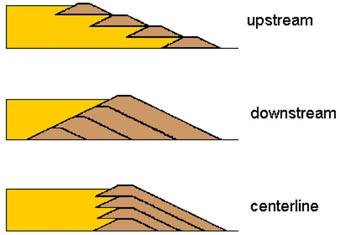

Second, while water supply dams are all of the down-stream-type construction, the construction of tailings dam can be either (1) downstream, (2) centerline, (3) upstream, or (4) a combination of any of the previous methods. Downstream construction is the safest type of construction from a seismic standpoint, but is also the most expensive option.

Upstream construction is the least secure because it relies on the stability of the tailings themselves as a foundation for dam construction (Davies 2002). Tailings, the ground waste rock from the grinding process, are generally placed behind the dam in water-slurry from the mill, and can remain saturated for long periods. Saturated, unconsolidated material is susceptible to liquefaction under seismic loading. But upstream dam construction, often using the coarse fraction of the tailings, is the least expensive dam construction option, and remains routinely employed in tailings dam construction.

EcoFlight

Centerline construction is a hybrid of downstream-type dam construction, and from a seismic stability standpoint the risk of failure lies between that of centerline and upstream types.

Why Tailings Dams Fail

The three leading causes for tailings dam incidents (unexpected events that occur to a tailings dam that poses a threat to dam safety or the environment and requires rapid response to avoid a likely dam failure) are overtopping, slope stability failures, and earthquakes (ICOLD 2001). Other long-term failure mechanisms for tailings dams include cumulative damage (e.g. internal dam erosion and multiple earthquake events), geologic hazards (landslides, etc.), static load induced liquefaction (the loss of strength in saturated material due to the buildup of pore water pressures unrelated to dynamic forces—most typically earthquakes), and changing weather patterns (ICOLD 2001).

Designing for both overtopping and earthquakes requires a prediction of the largest hydrologic or earthquake event the tailings dam will potentially experience during its lifetime, and in each of these instances the required lifetime is almost always perpetuity. The most conservative design criteria would involve assuming the maximum magnitude of hydrologic and seismic events a tailings dam could experience. Better data, better prediction methods, and employing conservative guidelines for assuming the worst-probable event are needed to remedy these problems. The time periods of concern are many millennia, but the existing seismic data collection is often limited to decades, at best.

EcoFlight

Dam incidents in the slope stability, foundation, and structural categories can be largely attributed to engineering design or construction failures. Rigorous design and construction practices, and adopting larger margins of safety in the designs, could address these issues, but tailings dam failure statistics indicate that there are still unresolved issues. Despite a basic understanding of the mechanisms that cause tailings dam failures and a convincing collection of empirical data on the impact of these failures, tailings dams have continued to fail at a relatively constant rate over the last five decades.

Regulatory Framework

EcoFlight

The design standards for most tailings dams are overseen by state dam safety agencies. There are no definitive federal regulations governing the construction and operation of metal-mine tailings dams, and only minimal federal involvement in the design of metal-mine tailings dams, usually only when there is a lack of state oversight (Szymanski and Davies 2004).

Current standards are focused mainly on water supply reservoir dams, and often lack guidance for tailings dams. The implementation of the standards depends largely on the professional judgment and experience of company consultants and government regulators. The advantage of this approach is that it allows regulatory and site-specific flexibility for tailings dam permits, but it also means that critical assumptions and specifications can vary significantly across similar dams in different locations. For example, one large tailings dam might be designed to withstand a 1-in-2,500-year flood or earthquake event, while a similar structure in another regulatory jurisdiction might be required to design for the 1-in-10,000-year event, which is generally assumed to be the largest possible event (ADNR 2005).

Summary

When we consider the recorded life of tailings dams structures (a century at most) compared to the length of time that they must function (millennia), the number of failures observed in the first century of their operation is not comforting. To the author, the statistics suggest a rather severe underestimation of risk continuing even today in tailings dam permitting and construction.

Our society still does not fully appreciate the long-term implications of storing billions of tons of potentially-harmful and semi-fluid waste in large impoundments. Advances to the technology for designing and identifying the long-term threats to these structures have usually been prompted after the fact, by dam failures. Post-failure analyses have identified the need for further analysis, and suggested the need for more conservative assumptions when specifying design requirements and the magnitude of natural events, like floods and earthquakes, that these structures must withstand in the long term (Szymanski and Davies 2004).

Policy direction from an organization with responsibilities to guide the safe construction and management of large dams, like ICOLD, tells us that we should be making conservative engineering decisions when designing tailings dams. Yet the failure rates demonstrate that the design specifications for the tailings dams have not always been based on the most conservative assumptions about the source and magnitude of the largest seismic event, and size of the largest hydrologic event, that might be experienced at a dam site. While these decisions may be rationalized in terms of defining reasonable risk, we must also acknowledge the very real pressure of present day economic costs to builders of the dam, if we are to lessen the assumed magnitudes of risk associated with the design of a tailings dam.

Making reasonable rather than conservative assumptions may increase the long-term risk to the society that will inherit the dam and the responsibility for managing the waste, and any future costs associated with the escape of impounded waste due to an unanticipated event. The potential for an unanticipated event should drive our initial design assumptions to be more conservative, not less.

Other recent events, such as the Gulf of Mexico oil spill, also demonstrate that we don’t fully appreciate the potential risks and consequences of some industrial hazards. The 2011 Honshu, Japan, earthquake released eight times as much energy as the maximum earthquake estimated by seismic risk experts (CIRES 2011) and caused a tsunami that crippled the Fukushima nuclear reactors. Our technology and science has limits; greater consideration should be given to those limits and a precautionary attitude adopted when making present-day decisions about difficult-to-estimate magnitudes of risk.

Chris Blake courtesy of MiningWatch Canada

References

ADNR (Alaska Department of Natural Resources). 2005.

Guidelines for Cooperation with the Alaska Dam Safety Program. Dam Safety and Construction Unit, Water Re-sources Section, Div. of Mining, Land and Water. June 30.

Arenas, J.M. and M. Méndez. 2002.

Aznalcóllar Mine accident in Seville (Spain): Lessons learnt four years later. Workshop on Mine and Quarry Waste—The Burden from the Past. Orta, Italy. May 27-28.

CIRES (Cooperative Institute for Research in Environmental Sciences). 2011.

Honshu Mw=9 Earthquake 11 March 2011. CIRES, National Oceanic and Atmospheric Administration (NOAA), and the University of Colorado at Boulder, April 9. http://cires.colo-rado.edu/~bilham/Honshu2011/Honshu2011.html

Davies, M.P. 2002.

Tailings Impoundment Failures: Are Geotechnical Engineers Listening? Geotechnical News, September, p. 31-36.

ICOLD (International Commission on Large Dams). 2001.

Tailings Dams, Risk of Dangerous Occurrences, Lessons Learnt from Practical Experiences. Bulletin 121.

ICOLD. 2006.

Improving Tailings Dam Safety, Critical Aspects of Management, Design, Operation and Closure. Bulletin 139. International Commission on Large Dams-United Nations Environmental Programme. Draft December 11.

MMSD (Mining, Minerals, and Sustainable Development Project). 2002.

Stewardship of Tailings Facilities. T.E. Martin, M.P. Davies, S. Rice, T. Higgs, and P.C. Lighthall, AMEC Earth & Environ-mental Limited. April.

Rico, M., G. Benito, A.R. Salgueiro, A. D´iez-Herrero, H.G. Pereira. 2008.

Reported tailings dam failures: A review of the European incidents in the worldwide context. Journal of Hazardous Materials 152: 846–852.

Szymanski, M.B. and M.P. Davies. 2004.

Tailings Dams Design Criteria and Safety Evaluations at Closure, Szymanski. Proceedings of British Columbia Reclamation Symposium.

UNEP (United Nations Environment Programme). 1998.

UNEP (United Nations Environment Programme). 1998.

WCOLD (World Commission on Dams). 2000.

Dams and Development. Earthscan Publications, November.

Wieland, M. 2001.

Earthquake Safety of Existing Dams for Irrigation and Water Supply in Rural Areas. Committee on Seismic Aspects of Dam Design. December.

Part of a series of articles titled Alaska Park Science - Volume 13 Issue 2: Mineral and Energy Development.

Last updated: June 15, 2015