Alger County Historical Society

In the 1840’s, traditional supplies of New England white pine had been exhausted and new sources were sought for the growing nation. The next state with large forests of the valuable white pine was Michigan. The state’s early lumber industry was strongly influenced by its geography. Like the lower peninsula, the Upper Peninsula had a network of creeks and streams which played a crucial part in transporting logs to the mills. Waterways also transported the finished product from the mills to markets on the lower lakes. The lumber would be piled high on the decks of modified sailing ships known as “barges” or lumber “hookers.” Later, railroads transported much of the lumber. It was Michigan white pine that provided the lumber for the building of the Midwest and prairie towns, and frequently was exported to European markets. It was also Michigan pine that rebuilt Chicago after its great fire. Pine was popular with the loggers because it floated easily and thus could be driven down rivers and streams to the mills, or assembled into rafts and transported over the open lakes. Denser hardwoods like maple could not easily be felled and rapidly dulled the saws in the mills. The unmarketable hardwoods were often burned in local kilns to make charcoal for iron production.

Prior to the big wheels, the logs were normally “skidded out” with oxen or horse teams to the main logging road. There they were loaded onto sleighs and hauled over ice roads to river banks where they were stored until spring. The ice roads were also primarily a Michigan innovation. The unique roads were made by running a sprinkler over a logging road during frigid nights. By morning, the normally rutted and rough trails were turned into sheets of ice. During the day heavy sleighs loaded with logs could rapidly move over them. The third innovation was the use of a narrow gauge railway to haul the logs instead of sleds or big wheels. First tried in Clare County, Michigan, during the winter of 1876-77 by Winfield Scott Gerrish, the narrow guage railroad rapidly became an industry standard. Upper Peninsula CruisingWhen the first surveyors walked the area of the park, the major forest type was the upland mesic, comprised of sugar maple, beech, yellow birch and hemlock. In the eastern area, north of Kingston Lake and along the lakeshore west to Beaver Lake, white pine and hemlock were predominant. Swamps were generally cedar, black spruce and hemlock. But it was the stands of large white and red pine that attracted the rugged early lumberjacks.William Burt, a noted Upper Peninsula surveyor, established the majority of the exterior township lines in 1841. The interior lines were established by William Ives and George Adair from 1850 to 1855. The township and section lines were vital for any logging operation. Without them it was impossible to establish proper ownership. Logging in the Pictured Rocks AreaThe first logging activity in Alger County occurred in 1877 when Joseph Weller began logging operations in the western area of Pictured Rocks. The logs were rafted to Munising Bay and Au Train Bay where they were assembled into booms and towed to Garden Island, Ontario. The logs were then squared and shipped to Liverpool, England. In 1879, Weller, operating on the mainland opposite Grand Island, was expected to ship 150,000 cubic feet of lumber, much of it squared.

Alger County Historical Society Sullivan's OperationsThe first extensive logging activity started in the park about 1880 in the vicinity of the Hurricane River and the Kingston Plains, also known as the “white rat plains” for a team of white horses used there.Extensive white pine areas were high-graded in 1882 by Thomas G. Sullivan. He logged both in Sanilac and later in Alpena for the Prentiss Lumber Company, one of the state’s largest operators. Sullivan’s U.P. camp operations eventually involved two groups of 150 men each, three yokes of oxen and 20 teams of horses. The oxen and horse teams were generally used for the skidding of the logs to the decking areas. The Sullivan operation lasted for three years as his crews cut 50 million feet of white pine from the forests within the lakeshore and in the Kingston Plains. The plains were logged over several times - over 3,000 acres of white pine were cut between 1882 and 1909. The plains also burned over several times, the latest in 1936. Sullivan’s logging was carried on mostly during the winter months, when the massive logs were hauled out on sleighs to the decking areas on the shore of Lake Superior. During the early spring, when the ice left the lake, the logs were rolled into the lake, assembled into rafts bound for either Grand Marais, Sault Ste. Marie or further down the lakes. RaftingRafting presented special problems on the Great Lakes, especially when they had to be towed some 200 miles of treacherous and storm swept water. To solve the difficulty, an entirely new type of log boom was developed. It consisted of threading a series of large pine logs, three or four feet in diameter on a heavy logging chain passed through holes drilled in the logs.The massive floating fence would surround a free mass of floating logs covering from ten to twenty acres and resembling a large balloon. In 1885, three million feet of logs were successfully towed to Bay City on Lake Huron from Lake Superior. In 1887, 30 million feet of logs were rafted down from Superior to Lake Michigan. Sullivan once rafted an eight million foot raft to Alpena, Michigan.

Alger County Historical Society Over the EdgeChutes for sending decked logs into the lake for rafting were fairly common. Besides the most famous at Devil’s Slide, east of Au Sable Point, there were slides at Miners Castle and one other location. The mammoth wood slide was built into the slope of the Grand SableDunes at a point approximately 300 feet above the lake surface. The angle of the slide would have been about 35 degrees. It isn’t clear which logging company used the slide, but it is most commonly associated with the operations of “daylight Johnny” Gillece, known for his efforts to maximize production from his crews. The logs were decked near the present parking area and then sent down the slide in the spring and worked into booms for the raft trip to the mills in Grand Marais. Today, there is no evidence of the slide. Grand MaraisIn 1897, Grand Marais sawmills were being supplied by 40 miles of temporary logging railroads. As soon as the timber in one area was exhausted the rails were shifted to a new, yet uncut area. Grand Marais also used the railroad as a method of transporting the finished lumber south to markets in the major cities. Grand Marais’ major products were in the form of square timbers, shingles or lumber. A number of different firms were involved in logging in the area, the biggest being the Alger-Smith Company which owned the Manistique Railroad and the Manistique Lumber Company.Grand Marais fell on hard times in 1885 when the pine mill closed due to a lack of logs. By 1890 the population was down to 177 people. Six years before, 300 people lived and worked in the thriving mill town. In 1893, however, Grand Marais went through a rebirth when the Manistique Railroad ran a 25 mile spur north from the town from Seney. By 1896, one mill alone was shipping 40 million feet a year and the population had boomed to 2,000. The good times didn’t last. With the last of the pine finally depleted, the Marais Lumber Company closed in 1909. A year later the railroad abandoned the line, and the Grand Marais slipped into a depression.

Alger County Historical Society Beaver Basin AreaOur knowledge of logging in the Beaver Lake area comes primarily from the Columbus Hall journals, which cover his travels in the area from 1883 to 1912. Hall was a Baptist minister and college professor from Indiana who vacationed in the Pictured Rocks area. As was common during the time, he dutifully recorded his experiences gained during his summer visits. Hall mentions a logging camp nine miles east of Beaver Lake and a Thurber’s camp. Hall also made frequent notes of members of his party eating at various logging camps.Hall referred to the use of Beaver Lake as a log storage site. The logs would be held behind a small dam on Beaver Creek prior to being sent downstream to Lake Superior where they would be rafted or loaded onto a waiting ship. According to Hall, when a vessel was expected, the loggers would open a sluice at the head of the dam, permitting both water and logs to slide down to Lake Superior. The logs would then be worked into booms and rafted away. In 1902, he noted that men were using horse drawn scoops to repair damage to the dam done during winter storms. The dam was still in use in 1904 and Hall mentioned opening it himself to spill some excess water from Beaver Lake. The Beaver Lake dam was identified as late as 1928 on a Michigan Department of Conservation map as the “old dam and footbridge.” A logging camp also existed at Beaver Lake from 1883-1906.

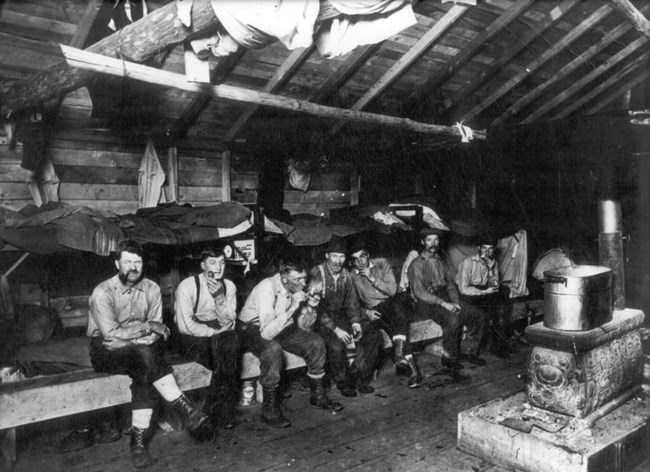

Alger County Historical Society No Place Like HomeThe logging camps located in isolated areas of the region were self-contained communities. Normally, the camps consisted of an office, company store (operated part time only with sales charged against pay due), bunk house, mess hall and kitchen, blacksmith shop and barn. The normal size for such camps was between 75 to 125 men, although larger camps were not uncommon. These camps usually lasted for between three to six years. When an area was logged out, the camps were simply abandoned or torn down and moved.Turning to HardwoodsWhile the pine provided the initial impetus for logging in the park, the hardwoods later became an important asset. Forests on the western edge of the park were cut from the early 1900’s until 1938, with the logs being taken to mills in either Marquette or Munising. Those in the eastern portion were cut on a large scale after 1940, primarily by the Cleveland Cliffs Iron Company for saw logs and pulp.In 1912 the company acquired an interest in the Great Lakes Veneer Company, and changed the name to the Munising Woodenware Company. This company produced a variety of woodenware and veneer products, all manufactured from local hardwoods. Today these are collector’s items. Most of the cedar in the park was selectively cut for railroad ties, shingles, posts and poles. In 1905 a cedar mill was built south of Grand Sable Lake by the Lombard and Rittenhouse Company. The mill produced products from the turn of the century until the 1930’s. Small cutting by contractors for cedar railroad ties was done throughout the park. The ties were for use by the Lake Superior and Ishpeming Railroad, employed in hauling iron ore from the Marquette Range mines to the lake docks. Munising MillsTowards the early part of the twentieth century several mills were built in Munising. Prominent among them was the Jackson Tindall Sawmill (1910). This mill was eventually purchased in 1944 by Ford interests, but wartime shortages caused an eventual abandonment. The Munising Paper Company was constructed in 1904 and by 1911 the plant was producing 70 tons of paper per day. In 1952 the company was purchased by the Kimberly Clark Corporation and is still in operation as Neenah Paper, Inc. |

Last updated: November 17, 2021