Suncor Energy

Open-pit mining of oil sands in northern Alberta began in 1967. In the past five decades operational practices in reclamation have adapted to changes in technology and regulatory requirements. One example is the first tailings pond in the region, which was actively used by Suncor Energy from 1967 to 1997. The surface of the tailings pond, now called Wapisiw Lookout, was reclaimed in 2010 to target a locally common boreal forest. It incorporates wetlands and local trees and shrubs, and provides wildlife habitat. The dyke slopes were reclaimed over a period of three decades, during which stakeholder expectations and regulatory requirements changed. Wapisiw Lookout provides an example of how the process of reclamation includes adaptive management to arrive at the final goal of closure and certification.

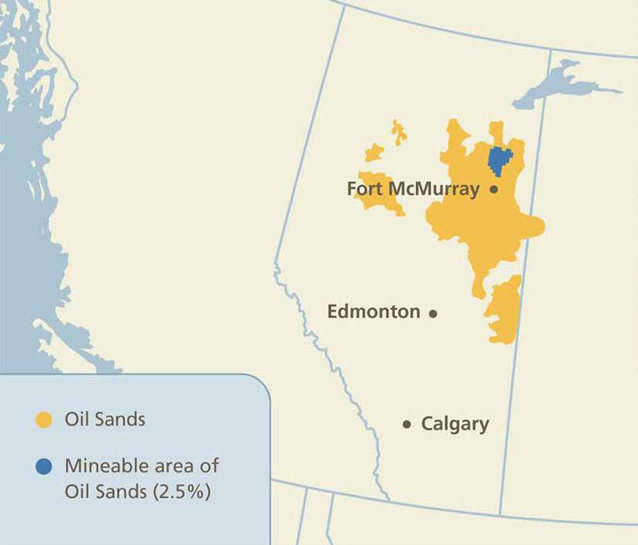

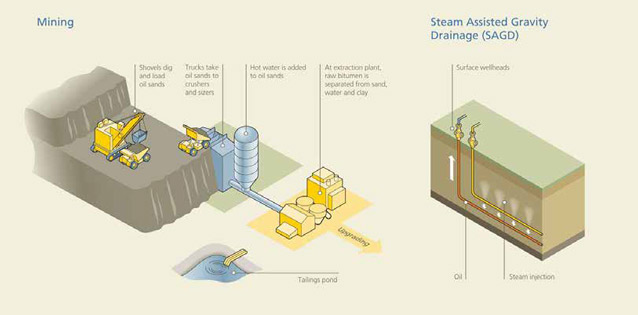

Alberta’s oil sands lie under 54,904 square miles (142,200 square kilometers) of Canada’s boreal forest. Only 2.5 percent of this area has deposits close enough to the surface to be mined by truck and shovel (Figure 1). Deeper deposits of oil sands are extracted through in situ technologies such as Steam Assisted Gravity Drainage (Figure 2).

Oil-sands mining began in the region in 1967 with Suncor Energy (then Great Canadian Oil Sands), followed by the start-up of Syncrude Canada Ltd. in 1978.

Oil sands are a mixture of bitumen (heavy hydrocarbons), water, sand, and fines. A hot-water extraction method is used to separate the bitumen from the sand and fines. The water is stored in tailings ponds to allow the sand and fines to settle out before reuse. Fluid fine tailings remain in the bottom of the pond and settle very slowly. Tailings ponds are a fundamental component of oil-sands mine operations because they facilitate reuse of water in the extraction process.

Pond 1 at Suncor, now called Wapisiw Lookout, was an active tailings pond between 1967 and 1997. As bitumen production increased, the inventory of fluid fine tailings increased, and the tailings pond was enlarged until the dykes rose to approximately 330 feet (100 meters) above the Athabasca River. The tailings pond had a final circumference of approximately two miles (three kilometers). Pond 1, at the end of its life as a tailings pond, contained a large volume of mature fine tailings (MFT). Mature fine tailings are comprised of approximately 70 percent water and 30 percent clay (by weight). These tailings were pumped from Pond 1 to another pond to be treated in a different tailings process, and coarse tailings sand was pumped into Pond 1. Replacement of the MFT with coarse tailings sand allowed Pond 1 to be reclaimed sooner to a terrestrial landscape, supporting progressive reclamation. The treatment of fluid fine tailings to a state enabling reclamation remains a major challenge for the industry.

Progressive Reclamation

The Environmental Protection and Enhancement Act of the Government of Alberta requires that land disturbed for oil-sands extraction must be conserved, reclaimed, and a reclamation certificate must be obtained. The conservation step requires salvage of reclamation material from the land surface and its storage for use in reclamation at a later date. Because oil-sands mines exist for the most part on public land, the land is ultimately returned to the province after reclamation. The Conservation and Reclamation Regulation states that the objective of conservation and reclamation is to return the land to an equivalent land capability. Land capability is defined in the regulation as the ability of the land to support a given land use, based on the evaluation of the physical, chemical, and biological characteristics of the land, including topography, drainage, hydrology, soils, and vegetation. The concept of equivalency must be considered and evaluated at multiple scales across the entire ecosystem.

The Government of Alberta recently changed the format by which disturbance and reclamation at oil-sands mines are tracked over time. The intent of this change was to provide more clarity for public reporting on the progress of reclamation (Table 1). Using Pond 1 as an example, it would have been classified as “disturbed” (used for mine or plant purposes) until 1997, when it would have moved into the “ready for reclamation” category. Between 1997 and 2009, MFT and process-affected water were removed from the pond and replaced with coarse tailings sand (Figure 3) to ensure a trafficable surface. A geosynthetic clay liner was used in the cover design of some areas of the pond surface, and swales were included to move surface water to a constructed wetland. From 2009 to 2010 approximately 65,000 truckloads of reclamation material (upland soil, peat-mineral mix, and coarse woody debris) were placed to a depth of 20 inches (50 centimeters) across the surface of the pond (Figure 4). Following this activity Pond 1 was moved into the “soils placed” category. In 2010, over 630,000 trees and shrubs were planted, moving Pond 1 into the “permanent reclamation” category.

At this time Pond 1 was named Wapisiw Lookout (Figure 5). According to local history, Captain Swan was the name of a Cree Indian who introduced the Hudson’s Bay Company to the oil sands in 1719. Swan translates into Cree as Wapisiw. Treaty rights of First Nations and their requirement for a closure landscape that supports traditional practices are important in defining reclamation outcomes. The majority of Wapisiw Lookout is now permanently reclaimed and undergoing reclamation monitoring (Figure 6).

Suncor Energy

Adaptive Management

Reclamation occurs on land that is disturbed over a period of decades, and under successive regulatory regimes. It can be challenging to determine which standards the reclamation will be assessed against at the time of reclamation certification. Perhaps the most significant limiting factor to reclamation is the life-of-mine reclamation material balance. If previous regulatory requirements did not require extensive salvage of upland soils and other reclamation material before disturbance, then it is highly likely that the quantity of reclamation material available in stockpile is insufficient to meet current approval requirements for placement depth. For example, prior to 2007, the typical reclamation material placement depth requirement was 8 inches (20 centimeters) over good and fair substrates. After 2007, this regulatory requirement was increased to 20 inches (50 centimeters). This change left a shortfall of reclamation material for disturbance carried out prior to 2007. Any reclamation material considered as excess prior to 2007 was not salvaged but disposed of with mine waste and irretrievably lost. Although the requirement for reclamation material placement depth was increased by the regulators in 2007, the one parcel of land certified by the Government of Alberta and returned to the province in 2008 was reclaimed to meet the previous 8-inch (20-centimeter) requirement.

Improvements in revegetation practice, wetland construction, and landform design are expected over time. In the mineable oil sands, this evolution of reclamation practice is typically guided by documents produced in a multi-stakeholder forum called the Cumulative Environmental Management Association (CEMA) and recommended to the Government of Alberta. Under CEMA’s Reclamation Working Group (RWG), guidance has been developed for landscape design, conservation of reclamation material, revegetation, wetland reclamation, design of end pit lakes, and criteria and indicators for reclamation certification. Moreover, RWG has recently implemented an adaptive management framework, wherein the guidance produced for reclamation will be evaluated on an empirical basis and revised where necessary. This approach is intended to provide assurance that the guidance is delivering the expected outcomes and is supported by a terrestrial long-term plot network.

Suncor Energy

The following guidance documents have been developed within CEMA, and are currently used by the oil-sands mine operators for planning and operations:

- Landscape Design Checklist (Revised RSDS Government Regulator Version) May 2005 (CEMA-RWG Landscape Design Subgroup 2005)

- Best Management Practices for Conservation and Reclamation Materials in the Mineable Oil Sands Region of Alberta (Alberta Environment and Water 2012)

- Guidelines for Reclamation to Forest Veg-etation in the Athabasca Oil Sands Region, 2nd Edition (Alberta Environment 2010)

- Guideline for Wetlands Establishment on Reclaimed Oil Sands Leases 2nd Edition (Alberta Environment 2008)

- End Pit Lakes Guidance Document (CEMA 2012)

- Criteria and Indicators Framework for Oil Sands Mine Reclamation Certification (CEMA 2012)

Suncor Energy

| Year | 2009 | 2010 | 2011 | 2012 |

|---|---|---|---|---|

| EPEA Approved Footprint | 331,504 | 333,980 | 337,661 | 359,041 |

| Mine Site Footprint | 156,380 | 167,625 | 179,160 | 198,445 |

| Plant Site Footprint | 9,996 | 8,715 | 8,813 | 10,094 |

| Total Active Footprint | 166,136 | 176,340 | 187,973 | 208,542 |

| Cleared | 45,454 | 42,124 | 42,130 | 50,496 |

| Disturbed: Used for Mine or Plant Purposes | 102,348 | 115,579 | 126,848 | 138,137 |

| Ready for Reclamation: No Longer Used for Mine or Plant Purposes | 2,255 | 972 | 618 | 922 |

| Soils Placed (Terrestrial, Wetlands & Aquatics) | 2,693 | 3,790 | 3,730 | 3,576 |

| Permanent Reclamation (Terrestrial) | 8,634 | 9,001 | 8,740 | 9,457 |

| Permanent Reclamation (Wetlands & Aquatics) | 2,661 | 2,945 | 2,841 | 3,002 |

| Temporary Reclamation (Terrestrial) | 2,133 | 1,928 | 3,066 | 3,031 |

| Certified | 257 | 257 | 257 | 257 |

An early guidance document developed within CEMA is the Land Capability Classification System for Forest Ecosystems in the Oil Sands (LCCS), 3rd Edition (Alberta Environment 2006). It was originally intended to be a tool for assessing equivalent land capability with a focus on forest productivity. Because of deficiencies in the LCCS that emerged with its use and a shift in focus to a broader set of reclamation outcomes, the LCCS is no longer current. In its place, the overarching expectation for terrestrial reclamation is the return of a locally common, self-sustaining boreal forest ecosystem that includes various types of wetlands. In the past, planting of nonnative trees such as hybrid poplar (Populus hybrids), Siberian larch (Larix sibirica), and caragana (Caragana arborescens Lam.) was acceptable and land use targeted the return of commercially viable forests. The focus now is to use locally sourced seed to re-establish the diversity found in the local boreal forest to return native plant species. Overlapping end land-use targets typically includes wildlife habitat, traditional land use, and commercial forestry.

Suncor Energy

Even though there were few defined criteria for reclamation in the mineable oil sands when Suncor began construction of Pond 1 in 1967, reclamation of the plateau at Wapisiw Lookout in 2009 to 2010 was considerate of current reclamation expectations. To this end it incorporated the following: drainage design including hummocks and wetlands (Figure 7); placement of 20 inches (50 centimeters) of reclamation material; revegetation with native species including wetland species of importance to local First Nation communities; and wildlife habitat including snags, bird and bat boxes, and rock piles (Figure 8).

Monitoring Towards Certification

Expectations for final closure are outlined in various sources: conditions of approvals issued under the Environmental Protection and Enhancement Act, reclamation and closure plans developed by the oil-sands mine operators and authorized by the regulator, and various guidance documents produced by CEMA including the Criteria and Indicators Framework for Oil Sands Mines Reclamation Certification (CEMA 2012). Further work remains to define criteria for, and monitor progress toward, certification.

Suncor Energy

The assessment of equivalent land capability is typically based on an evaluation of the physical, chemical, and biological characteristics of the land, including topography, drainage, hydrology, soils, and vegetation. It is required that a reclaimed landform be integrated with the surrounding landscape.

Permanently reclaimed landforms may be monitored for 20 or more years before a reclamation certificate is applied for. For example, performance surveys are conducted between 11 and 20 years after planting at sites where commercial forestry is one of the end land uses. Monitoring the effectiveness of reclamation ensures that reclaimed sites are certified only when they meet previously established benchmarks. Effective reclamation monitoring programs need indicators that demonstrate that ecosystem functions are established and plant community composition and structure are developing on an acceptable trajectory to support the end land-use objectives.

Suncor Energy

Outstanding Challenges

Oil-sands mining is a relatively young industry, with other operators joining Suncor and Syncrude Canada Ltd. in the 1990s and 2000s. The companies have historically worked together with regional stakeholders in forums like CEMA and developed guidance for reclamation through applied research and development programs. Going forward, new organizations like Canada’s Oil Sands Innovation Alliance (COSIA) will continue to develop technology to improve tailings management, terrestrial and wetland reclamation, and design of end-pit lakes.

In a region that will be connected by open-pit mines, the spatial and temporal integration at lease boundaries remains a challenge. Management of surface water across the region post-closure and connectivity of wildlife habitat must be considered in project design up front and not just during reclamation and closure. There are still gaps in regulatory expectations at closure, especially for water quality and fluid fine tailings. There is a strong commitment from the companies, regulators, and stakeholders to find the answers and move forward with adaptive management.

Suncor Energy

References

Alberta Environment. 2006.

Land Capability Classification System (LCCS) for Forest Ecosystems in the Oil Sands, 3rd Edition. Volume 1: Field Manual for Land Capability Determination. Prepared for Alberta Environment by the Cumulative Environmental Management Association. < a href="http://www.environment.gov.ab.ca/info/library/7707.pdf">Download this report

Alberta Environment. 2008.

Guideline for Wetland Establishment on Reclaimed Oil Sands Leases, 2nd Edition. Prepared by Harris, M.L. of Lorax Environmental for the Wetlands and Aquatics Subgroup of the Reclamation Working Group of the Cumulative Environmental Management Association, Fort McMurray, AB. December 2007. < a href="http://www.environment.gov.ab.ca/info/library/8105.pdf">Download this report

Alberta Environment. 2010.

Guidelines for Reclamation to Forest Vegetation in the Athabasca Oil Sands Region, 2nd Edition. Prepared by the Terrestrial Subgroup of the Reclamation Working Group of the Cumulative Environmental Management Association, Fort McMurray, AB. December 2009. < a href= http://www.environment.gov.ab.ca/info/library/8269.pdf">Download this report

Alberta Environment and Water. 2012.

Best Management Practices for Conservation of Reclamation Materials in the Mineable Oil Sands Region. Prepared by MacKenzie, D. for the Best Management Practices Task Group for the Terrestrial Subgroup of the Reclamation Working Group of the Cumulative Environmental Management Association, Fort McMurray, AB. March 9, 2011. Download this report

(CEMA) Cumulative Environmental Management Association. 2005.

Landscape Design Checklist (Revised RSDS Government Regulator Version). May. CEMA-RWG Landscape Design Subgroup 2005. Download this report

(CEMA) Cumulative Environmental Management Association. 2010.

A Framework for Reclamation Certification Criteria and Indicators for Mineable Oil Sands. Prepared by Poscente, M. for the Reclamation Working Group of the Cumulative Environmental Management Association, Fort McMurray, AB. December 10, 2009. < a href="http://cemaonline.ca/index.php/news-a-events/cema-press-releases/89-cema-news/press-releases/press-release-articles/198-press-release-cema-announces-criteria-a-indicator-framework-for-reclamation-certification-february-14-2013">Download this report

(CEMA) Cumulative Environmental Management Association. 2012.

End Pit Lakes Guidance Document. Download this report

Part of a series of articles titled Alaska Park Science - Volume 13 Issue 2: Mineral and Energy Development.

Last updated: June 15, 2015