UAF Archives, Stanton Patty Collection

Gold is probably the most widely distributed of precious metals . . . but regardless of whether the gold strike is found on the frozen tundra or the burning desert, Hillman Drills and gold-sampling equipment are always in evidence.

—C. Kirk Hillman brochure, 1930s

When the first gold rush stampeders reached Coal Creek in August 1898 they carried with them the primitive tools of the small-scale placer gold miner: picks, shovels, and prospecting pans. The sluice boxes they built along the creek valley proved to them that there was gold in paying quantities, but reaching it and processing large amounts of gravel was an arduous task. In 1934, when General Alexander McRae decided to mine Coal Creek on an industrial scale, his company, Gold Placers, Inc., would succeed only if he could guarantee that his gold dredge followed the band of subterranean gold called a paystreak. He would need not only a dredge but a specialized drill.

UAF Archives, Stanton Patty Collection Gold Placers, Inc. general manager Ernest Patty knew that “prospecting with a dredge” was pure folly. Dredge owners elsewhere in Alaska had gone broke while blindly pointing their enormous machines this way and that, all the while losing money with the cost of operation. Patty would not make that mistake, and he decided on the most modern drill designs from C. Kirk Hillman Company in Seattle, Washington.

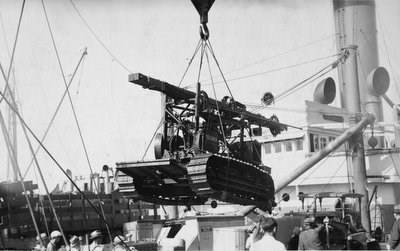

In the early 1930s, Hillman began manufacturing gasoline-powered drills for the mining industry and liked to call himself “Hillman the Drillman.” His marketing strategy depended upon light-weight design and mobility, and he advertised that around the world his drills were being “transported by dog teams, mules, elephants, trucks, and planes.” He called his lightest model the “Airplane drill” because it could be disassembled and loaded onto small aircraft bound for distant mining districts; all-steel construction even eliminated breakage when the parts were dropped from the air. The company’s larger model was the “Prospector,” which could be mounted on a truck or fitted with Caterpillar treads, wheels, or skids depending on the customer’s needs.

UAF Archives, Stanton Patty Collection Work Begins at Coal Creek

After Gold Placers, Inc. purchased gold claims from Coal Creek old-timers, the company purchased one of each model of Hillman drill and began to systematically drill the length of the valley. As Patty explained,

A churn drill made prospecting for signs of gold easy because the bit both rotated and pounded downward. Once water was introduced to the hole, the resulting slurry of pulverized rock (and bits of gold) could be pumped out and tested. By drilling and testing at regular intervals, a map could be made of an entire creek valley based on value calculations of cents per cubic yard. With this map in hand, the dredge operators could direct their earth- eating machine toward the highest concentrations of gold.

Decades of Dredging

Each year the crew of the Coal Creek dredge continued to drill to refine their understanding of the meandering paystreak. The company also sent the “Prospector” drill and a crew twelve miles away to test gravels in the Charley River drainage. By that time the Caterpillar treads on the drill had been replaced by log skids reinforced by steel bands for dragging the rig overland with a bulldozer. The Coal Creek dredge stopped major operations in 1957, and today the drills, the dredge, and many other machines remain as reminders of the heyday of industrial gold mining in what is today Yukon-Charley Rivers National Preserve.

NPS/Chris Allan |

Last updated: December 24, 2015