NPS Photo by Josh Spice I could see the finer gravel, which would be sand and gold, dropping through slots in the screen and onto gold-saving sluices. —Ernest Patty, 1936

The industrialization of gold placer mining along the Yukon River corridor demanded tremendous ingenuity and capital investment. Before the arrival of gold dredges like the one at Coal Creek (and its twin in neighboring Woodchopper Creek), miners worked mostly with hand tools, sluice boxes, and small steam boilers for thawing permanently frozen ground. The dredges by contrast could process 3,000 cubic yards of gravel every 24 hours, making relatively poor ground pay handsomely. Weighing hundreds of tons, the mighty machines moved across the landscape by floating in a lake of their own making. As a dredge’s buckets ate away at the earth in its path, the dredge floated forward, leaving behind arc-shaped mounds of discarded rock called tailings. Today piles of tailings cover seven miles of the Coal Creek streambed.

NPS, Bill Lemm Coll The man who financed the Coal Creek dredge was General A. Alexander McRae, a wealthy Canadian investor who made a fortune in the lumber, salmon canning, and whaling industries and earned his rank in Europe during WWI. In 1933 McRae contacted Ernest Patty, who was then dean of the university’s School of Mines in Fairbanks, and asked him to recommend potential gold mining areas. Together they examined sites across Alaska before settling on Coal Creek. Just as McRae and Patty were negotiating to buy claims from the old-timers on the creek, the price of gold rose from $20 to $35 an ounce. In short order Patty resigned his university post and became the vice-president and general manager of Gold Placers, Inc.

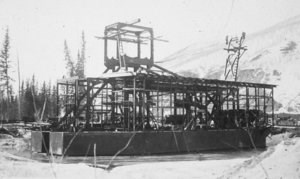

The next order of business was to import a dredge, which they purchased from the Walter W. Johnson Co. in Oakland, California for $156,000. But delivery (included in the cost) would not be easy. After it was built, the dredge was disassembled, crated, and loaded aboard a steamship destined for Skagway. Then it was loaded onto the White Pass railroad for transport to Whitehorse, Yukon. From there it traveled by paddlewheel steamboat on the Yukon River to Slaven’s Roadhouse at the mouth of Coal Creek. Next the men hired to build the dredge had to unload the 400 tons of steel parts using a combination of pulleys, rollers, ramps and Caterpillar tractors. But, not until they moved the whole outfit seven miles up the creek drainage could the real construction begin.

NPS/Chris Allan

UAF Archives, Stanton Patty Collection One of the challenges of placer mining on an industrial scale in northern Alaska is the need to thaw large sections of permafrost ahead of the dredge. At Coal Creek the process of thawing began with bulldozers that stripped away the trees and brush and the layer of tundra that served as an insulating blanket for the ice below. This exposed the frozen, muddy ooze called muck that varied in depth between 6 and 26 feet. To remove the muck, they used pressurized water from a hillside ditch to blast away a few inches each day. Once the gravel was exposed, they employed a third tactic: injecting steam into the earth with steel pipes tipped with chisel bits called steam points. Because producing so much steam took time and money, the miners later

NPS Photo by Josh Spice When the dredge was in operation it traveled for miles along the creek valley, making it necessary to construct a camp for the workers built on log skids that could periodically be moved. Today the Coal Creek mining camp has been restored by the National Park Service and includes a number of bunkhouses, a mess hall, an assaying and refining office, and machine shops. The camp, gold dredge, and many other artifacts of the industrial gold mining era are all part of Yukon-Charley Rivers National Preserve. National Park Service Natural Resource Report: Industrial placer gold mining is a messy business. To make it pay, miners turn the earth upside down by excavating the richest mineral-bearing gravels and casting away all but the dust, flakes and nuggets of gold. This operation requires not only men and machines but also chemicals, heavy metals, and large amounts of petroleum-based fuels and lubricants. And when the mining is done, these hazardous materials often remain. [...] This was the situation in 1986 when Yukon-Charley Rivers National Preserve acquired a group of mining claims along Coal Creek, a tributary of the Yukon River roughly eighty miles from the U.S.-Canada boundary. The following is the story of gold mining at Coal Creek and the impressive campaign launched by park managers to make the Coal Creek watershed safe for use by the public and by National Park Service employees. The requested video is no longer available.

|

Last updated: April 6, 2020