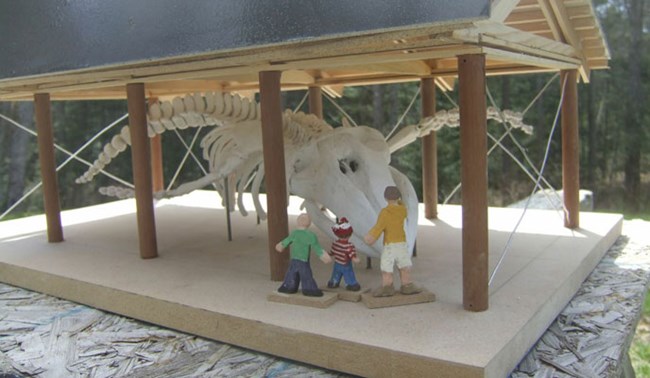

NPS Photo Putting Snow Back Together Before Whales and Nails could begin articulation, several decisions had to be made with regards to the final exhibit. Probably the most important decision, and one that could never be changed, was the posture. The park had a strong desire to showcase Snow's skeleton in a natural position that would allow for maximum viewing opportunities and accurately reflect the anatomy and movement of a humpback whale. Many resources were referenced to help the park guide Whales and Nails in this decision. To begin the process, Dan created three, beautiful 1/4" scale models using modeling clay, pipe cleaners, and recycled wood. Each posture showed the skeleton with varying degrees of curvature in the spine. After much discussion and feedback from the park's Facebook followers, most everyone was in favor of posture #3 - the whale exhibiting the most motion. Once a consensus was reached, a second model was produced at 1/2" scale that included pedestrians, the height and visibility of the blowhole, and mounts and attachments for installation. We had a winner!

NPS Photo Preliminary Articulation Before Snow's skeleton could be articulated and put on display in Bartlett Cove, Whales and Nails had to first make sure all the bones fit together in Maine. Dan turned his back yard into a whale exhibit! He built a platform to simulate the permanent exhibit space using the hardware that would be necessary to hold the 3,500 lb. skeleton, tools, mounts, welding equipment, etc. The skeleton was prepared using a method of modular construction where the primary articulation occurred at the shop of Whales and Nails. The completed modules - skull, spine sections, and left and right flippers, were then transported back to Glacier Bay intact for final assembly during the installation. The rib cage and lower jaw bones were fitted during the preliminary assembly in Maine, but were then transported individually and articulated during installation. Here's how it was done.

The Spine The central piece of the articulation was the thirty-one foot spine and fourteen foot skull. The fifty-seven individual vertebrae (thoracic, lumbar, caudal) and seven fused (cervical) vertebrae in the spine were pieced together in sections so they could be easily be moved and transported back to Glacier Bay for installation. This was the anchor for the entire articulation project. The flippers and ribs were added later. To start, a hole was drilled through each vertebrae so that it could be threaded on to an 8' stainless steel pipe. A long pilot drill bit was used to center a drill hole through the middle of each bone. Then, a 4" hole saw was used to core out the center. Some of the bones were over 12" deep which required the team to complete the task in multiple steps - drill, chisel out the core, drill futher, chisel, etc. Dan had to specially make chisels that were heavy, but thin enough to allow the team to work deep in the vertebrae. "We found it best to only work from one side because even a slight misalignment can cause the hole saw to bind and is dangerous - not to mention results in a sloppy hole." To simulate cartilage between the bones, urethane foam was used to fill the spaces. The expanding foam acted like a glue to compress the vertebrae against one another and help hold them in place. Once dry, the cartilage was covered with epoxy and a final layer of putty.

NPS Photo The Ribs Snow had a total of twenty-eight ribs, fourteen on each side. Each rib was fitted with custom hardware that enabled it to connect to its corresponding vertebra. Some ribs weigh over fifty pounds each, which means several of the vertebra support over one hundred pounds of weight per bone. The Skull The skull underwent extensive repairs at the Whales and Nails shop and only the rostrum was attached during the preliminary articulation. The left and right mandibles (left and right jawbones) were put in place during final installation in Bartlett Cove.

NPS Photo The Flippers Each of Snow's flippers is made up of four digits (fingers) and three arm bones (radius, ulna, and humerus). To create each flipper module, Whales and Nails joined all these bones together using epoxy and metal rods. Large metal pipes anchored to the ground, called stem mounts, were used to support the weight of each flipper. They attached to the shoulder blade (scapula) with a small connection. The spaces between the bones were filled with caulk, then covered with gray taxidermy putty to simulate cartilage. The requested video is no longer available.

Grand Opening |

Last updated: August 16, 2023