Last updated: March 29, 2023

Article

Hopewell Furnace: A Pennsylvania Iron-making Plantation (Teaching with Historic Places)

This lesson is part of the National Park Service’s Teaching with Historic Places (TwHP) program.

The splash and creak of the turning water wheel and the swishing roar of the furnace "blast" never stopped. By day, black charcoal dust swirled from the furnace and blanketed the whole village; by night, only a flickering red glow lit the sky. The rhythmic noises, the ever-present soot and dust, and the unpleasant smell emanating from the furnace were reassuring to workers at Hopewell Furnace during its years of operation (1771-1883). As long as the furnace was "in blast," their jobs were safe. In many ways, these ironworkers were better off than industrial workers in the cities. Here in rural Pennsylvania, they could escape to the woods, fields, and creeks. And, although their work was often dangerous, they were relatively well paid.

Hopewell Furnace, now a national historic site, lies in a setting of forested hills and valleys along French Creek in Berks County in southeastern Pennsylvania. It provides a glimpse into the early days of the iron and steel industry that played a central role in the growth of America as an industrial nation.

About This Lesson

This lesson is based on the National Register of Historic Places registration file, "Hopewell Furnace National Historic Site," the National Park Service visitor's guide to Hopewell Furnace, and the National Park Service handbook on Hopewell Furnace National Historic Site. It was written by Rita G. Koman, an educational consultant. The lesson was edited by Fay Metcalf, Marilyn Harper, and the Teaching with Historic Places Staff. TwHP is sponsored, in part, by the Cultural Resources Training Initiative and Parks as Classrooms programs of the National Park Service. This lesson is one in a series that brings the important stories of historic places into classrooms across the country.

Where it fits into the curriculum

Topics: This lesson could be used in American history, social studies, and geography courses in units on the growth of the American economy during the early National period.

Time period: Early National

United States History Standards for Grades 5-12

Era 4: Expansion and Reform (1801-1861)

Standard 2A- The student understands how the factory system and the transportation and market revolutions shaped regional patterns of economic development.

Curriculum Standards for Social Studies

Theme I: Culture

- Standard A - The student compares similarities and differences in the ways groups, societies, and cultures meet human needs and concerns.

- Standard C - The student explains and give examples of how language, literature, the arts, architecture, other artifacts, traditions, beliefs, values, and behaviors contribute to the development and transmission of culture.

- Standard D - The student explains why individuals and groups respond differently to their physical and social environments and/or changes to them on the basis of shared assumptions, values, and beliefs.

- Standard E - The student articulates the implications of cultural diversity, as well as cohesion, within and across groups.

- Standard B - The student identifies and uses key concepts such as chronology, causality, change, conflict, and complexity to explain, analyze, and show connections among patterns of historical change and continuity.

- Standard C - The student identifies and describes selected historical periods and patterns of change within and across cultures, such as the rise of civilizations, the development of transportation systems, the growth and breakdown of colonial systems, and others.

- Standard E - The student develops critical sensitivities such as empathy and skepticism regarding attitudes, values, and behaviors of people in different historical contexts.

- Standard A - The student elaborates mental maps of locales, regions, and the world that demonstrate understanding of relative location, direction, size, and shape.

- Standard G - The student describes how people creates places that reflect cultural values and ideals as they build neighborhoods, parks, shopping centers, and the like.

- Standard H - The student examine, interprets, and analyze physical and cultural patterns and their interactions, such as land uses, settlement patterns, cultural transmission of customs and ideas, and ecosystem changes.

- Standard I - The student describes ways that historical events have been influenced by, and have influenced physical and human geographic factors in local, regional, national, and global settings.

- Standard A - The student demonstrates an understanding of concepts such as role, status, and social class in describing the interactions of individuals and social groups.

- Standard B - The student analyzes group and institutional influences on people, events, and elements of culture.

- Standard C - The student describes the various forms institutions take and the interactions of people with institutions.

- Standard A - The student examines issues involving the rights, roles and status of the individual in relation to the general welfare.

- Standard A - The student gives and explain examples of ways that economic systems structure choices about how goods and services are to be produced and distributed.

- Standard B - The student describes the role that supply and demand, prices, incentives, and profits play in determining what is produced and distributed in a competitive market system.

- Standard C - The student explains the difference between private and public goods and services.

- Standard D - The student describes a range of examples of the various institutions that make up economic systems such as households, business firms, banks, government agencies, labor unions, and corporations.

- Standard E - The student describes the role of specialization and exchange in the economic process.

- Standard F - The student explains and illustrate how values and beliefs influence different economic decisions.

- Standard G. The student differentiates among various forms of exchange and money.

- Standard H - The student compares basic economic systems according to who determines what is produced, distributed, and consumed.

- Standard J - The student uses economic reasoning to compare different proposals for dealing with a contemporary social issue such as unemployment, acid rain, or high quality education.

- Standard A - The student examines and describes the influence of culture on scientific and technological choices and advancement, such as in transportation, medicine, and warfare.

- Standard B - The student shows through specific examples how science and technology have changed people's perceptions of the social and natural world, such as in their relationship to the land, animal life, family life, and economic needs, wants, and security.

- Standard C - The student describes examples in which values, beliefs, and attitudes have been influenced by new scientific and technological knowledge, such as the invention of the printing press, conceptions of the universe, applications of atomic energy, and genetic discoveries.

Objectives for students

2) To identify the steps in making iron and iron products at Hopewell Furnace.

3) To trace the effects of national events on Hopewell Furnace and its owners.

4) To describe how work helped determine social status within the Hopewell community.

5) To compare and contrast the early economic development of their own community with that of the Hopewell Furnace community.

Materials for students

The materials listed below either can be used directly on the computer or can be printed out, photocopied, and distributed to students. The maps and images appear twice: in a smaller, low-resolution version with associated questions and alone in a larger version.

1) two maps showing Hopewell Furnace and the surrounding area;

2) three readings about iron-making and the Hopewell Furnace community;

3) four photos of the charcoal-making process, the historic site today, and some Hopewell Furnace products;

4) two illustrations of the iron-making process and of the restored Hopewell Furnace Historic Site.

Visiting the site

Getting Started

Inquiry Question

(National Park Service, Jackson Kemper, photographer)

What might this man be doing?

Setting the Stage

The iron tools and household utensils necessary in the early days of colonial America were either brought along by settlers from Europe or imported at high cost. The colonists quickly realized that, even though it violated their country's laws, they needed to manufacture their own iron products. The construction of charcoal-burning furnaces to produce iron was possible only where the necessary natural resources--iron ore, limestone, hardwood forests, and water--were readily available. The Middle Atlantic colonies had an abundance of these raw materials.

William Penn lured colonists to Pennsylvania by stressing not only religious toleration, but also the fact that his colony was rich in natural resources, including good quality iron ore and extensive forests. Immigrants from Europe poured into the colony. Large numbers settled in Philadelphia and its surrounding region. These settlers needed everyday objects such as tools, nails, horseshoes, and cooking utensils. Many small iron-making furnaces were built in southeastern Pennsylvania to take advantage of that market. By the time of the American Revolution, there were approximately 65 ironworks concentrated in southeastern Pennsylvania.

Hopewell Furnace was established in 1771 and supplied shot and cannon for the Continental Army and Navy during the Revolutionary War. Reflecting the economic problems of the young Republic, the furnace led a troubled life and often changed hands during the last years of the 18th century. In 1800, it entered a new period of prosperity under new owners. Between 1825 and 1844, Hopewell Furnace supplied a wide variety of iron products to cities all along the east coast, including the popular "Hopewell Stove." The furnace continued to operate until the 1880s, but never again achieved the success of the 1830s and 40s. Today the National Park Service administers the site as Hopewell Furnace National Historic Site.

Locating the Site

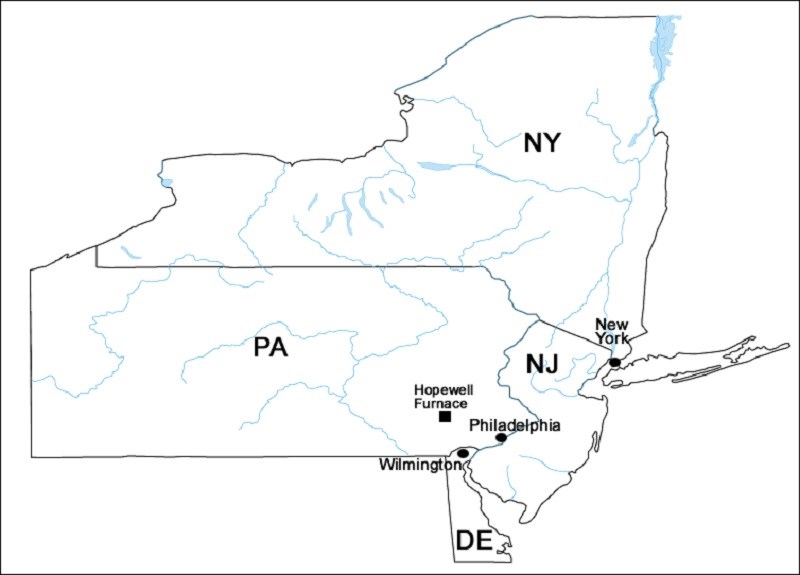

Map 1: Pennsylvania and surrounding region.

Map 2: Southeastern Pennsylvania in the mid-19th century.

NPS map

Hopewell Furnace operated as part of a complex network of furnaces (turning iron ore into iron and producing cast iron products), forges (refining cast iron into wrought iron products), mines, and markets in southeastern Pennsylvania and beyond. This map shows some of the mines and ironworks wholly or partly owned by the same men who owned Hopewell Furnace in the 1830s.

Questions for Maps 1 and 2

1. Locate Hopewell Furnace and Philadelphia on Maps 1 and 2.

2. The map key on Map 2 identifies other categories of iron-related sites. How many can you locate that are within 10 miles of Hopewell? Why were there so many furnaces and forges in this region?

3. Early 19th-century iron-making required easily mined iron ore, a dependable water supply to provide the blast for the furnace, extensive hardwood forests for charcoal, and limestone to remove the impurities from the ore. Which of these are easily identified on Map 2?

4. Success in iron making required markets where products could be sold and transportation to get them there. Using Map 2, identify cities that might have served as markets. Use the map key to calculate how far these cities were from Hopewell Furnace. What means of transportation to carry iron products to these markets can you identify on Map 2?

Determining the Facts

Reading 1: The Work at Hopewell Furnace

During the Colonial and early National periods of America's history, molded or cast-iron articles were the end products of a fairly simple process developed in the ancient world. The raw materials needed--iron ore, limestone, and hardwood forests for charcoal--were all available in the Hopewell area in Pennsylvania. Miners dug the ore from nearby open-pit mines and washed it in the stream. Limestone was cut from local quarries. Teamsters carried the ore and the limestone to the furnace. Charcoal making was an exacting and dirty job. More than 100 part-time woodcutters spent the winter cutting and splitting the hardwood needed to fuel the furnace. The wood was hauled to the coaling areas and made into charcoal during the spring, summer, and fall by skilled colliers. This was done by slowly charring it in "pits" under carefully controlled conditions. The coaling process was touchy, for enough heat had to be produced to expel the tar, moisture, and other substances from the wood without consuming the wood itself. Once the process was complete, the charcoal was raked out, cooled, and taken by wagon to the furnace where it was stored in the charcoal house.

With supplies of all the ingredients on hand, the founder, or furnace supervisor, directed the charging of the blast furnace--a tall, stone structure shaped like a flattened pyramid. An elevated walkway connected the furnace with storage areas on the furnace bank. Fillers rolled carts and wheelbarrows of charcoal, iron ore, and limestone over the walkway and dumped them into the top of the furnace. At approximately half-hour intervals, day and night, they repeated the process. A large wooden water wheel in a pit next to the furnace drove a pair of blowing tubs. These large wooden barrels fitted with pistons provided the blast of air that helped raise the temperature in the furnace to 2600-3000 degrees Fahrenheit, hot enough to convert iron ore into iron. In front of the furnace was the cast arch where the molten iron was periodically tapped. The furnace was allowed to cool down only when repairs were necessary or the supply of charcoal ran out. During the 1830s, it was usually "in blast" for approximately eleven and a half months a year.

Profits were greater for high quality iron that could be cast into saleable articles than for less-pure metal that required additional refining. The founder was responsible for controlling quality by regulating the precise balance of the ingredients and the blast of air. When he tapped the furnace, the founder decided whether the molten iron met the demanding standards for casting. If the flow contained too many impurities, the red-hot iron was run into beds dug in the sand floor of the cast house. Guttermen were responsible for preparing the beds and digging the channels into which the iron flowed. Because the pattern formed by the beds reminded early observers of a litter of nursing piglets, the resulting product was known as "pig iron." The pigs were shipped to forges for further processing.

If the molten iron was high quality, the founder rang the cast house bell, calling the skilled moulders to ladle the fiery liquid into their waiting sand molds. The founder's reputation, as well as his pay, was based on the percentage of high quality casting iron his furnace produced. Moulders were also paid according to the quality and quantity of their individual work. They received higher wages if they cast intricate and difficult designs. A mold was made by compacting a special sand around a wooden pattern in an enclosed box, or flask. It required great precision to keep stray grains of sand out of the pattern space. The cooled castings were taken from the cast house to the cleaning shed, where sand was brushed off and rough edges filed.

Hopewell workers manufactured a wide variety of pots, skillets, flat irons, wheels, sash weights, anvils, hammers, and grates, but the casting of iron stove plates was the mainstay of the operation through the 1840s. Many different types, including the famous "Franklin Stove," were produced in the casting house. Coal and wood-burning "Hopewell stoves" were well-known for their high quality, but some dealers furnished casting patterns which carried their own names rather than Hopewell's. Dealers usually completed the final assembly of the stoves. By 1844 Hopewell moulders had produced more than 65,000 stoves.

Questions for Reading 1

1. How was the furnace "charged" or fed?

2. Construct a flowchart showing the process of turning iron ore into finished products. Identify the workers responsible for each stage of the process. Why do you suppose there were so many different jobs?

3. Why do you think the furnace operated 24 hours a day whenever possible?

Reading 1 was compiled and adapted from the National Park Service's handbook, Hopewell Furnace: A Guide to Hopewell Furnace National Historic Site, Pennsylvania (Washington, D.C.: Division of Publications, National Park Service, Handbook 124, 1983).

Determining the Facts

Reading 2: Owner and Ironmaster

Clement Brooke was Hopewell ironmaster from 1816-1848 and part owner from 1827-1861. A good ironmaster had to be a combination of capitalist, technician, market analyst, personnel director, bill collector, purchasing agent, and transportation expert; Clement Brooke seems to have had all the necessary qualities. Liked and respected by his employees, his partners, and his customers, Brooke earned a reputation as one of the best ironmasters in Pennsylvania.

In 1800 at age 16, Brooke began his iron-making career as assistant clerk at Hopewell Furnace, which his father and uncles had recently purchased. He also worked part-time at night supervising the filling of the blast furnace. By the time he was 20, he had become the clerk and kept the records of all company operations. He followed that job with one as caretaker of the property, supervising general maintenance during a period when the furnace was not operating. He was also in charge of the stamping mill, which crushed slag to reclaim the small amounts of iron contained in it. Although he lacked formal education, his practical experience embraced all aspects of furnace operation. In 1816 he became resident manager and ironmaster at Hopewell Furnace with a salary of $600 a year plus rent-free use of the ironmaster's mansion. By 1827, he was part owner as well.

During Brooke's early years at Hopewell Furnace, the United States was embarking upon an era of economic expansion. Warfare between England and France during the first years of the 19th century, the Embargo Act of 1807, and the War of 1812 restricted access to imported products and encouraged the growth of domestic industries such as textile mills and ironworks. Once peace was restored, Congress enacted high tariffs to protect these "infant industries" from foreign competition. The Federal Government also encouraged "internal improvements," like turnpikes and canals, which made shipping industrial products to market quicker and cheaper. These changes combined with technical improvements made by the new owners to make Hopewell Furnace a highly profitable operation. Between 1820 and 1825, iron production nearly doubled. It had doubled again by the mid-1830s, the most productive and profitable period of Hopewell's history.

Much of Hopewell's success during the 1830s and '40s can be credited to Clement Brooke. He found new markets for the furnace's products and was responsible for the decision to concentrate on castings rather than pig iron. He purchased additional woodlands for charcoal and sought other sources of iron ore. He increased the labor force by half, expanding production without sacrificing quality. He enlarged the Big House (the ironmaster's mansion) to include room for 15 servants and for itinerant workers. He built more tenant houses; enlarged the company store, spring house, and barn; added a formal garden; and built a schoolhouse across the creek from the furnace.

In 1837, a financial panic led to a five-year depression. The furnace was just coming off the longest continuous blast in its history--from January 3, 1836, to April 10, 1837. At the same time, charcoal-fired iron furnaces were becoming obsolete, replaced by new ironworks that used hard coal to produce iron more efficiently. In 1844, probably because of declining demand and increasing costs, Clement Brooke ended large-scale stove-plate casting. During its last four decades, Hopewell mainly produced pig iron, for which demand was growing in a rapidly industrializing society. Although the furnace managed to turn a profit most years before it closed in 1883, it never again enjoyed the prosperity of the 1825-44 period.

Brooke retired as ironmaster in 1848, at age 64, and moved into a house in nearby Pottstown. He was a wealthy man for his time; besides his half share in Hopewell, he owned shares in five other furnaces and forges, had an interest in coal mines in Schuylkill County, and owned stock in several railroad companies. In 1859 he moved to Philadelphia, where he died two years later at the age of 76. Clement Brooke's association with Hopewell spanned more than half a century.

Questions for Reading 2

1. How did Clement Brooke become involved in the iron business?

2. In what ways did he improve Hopewell Furnace?

3. How did he contribute to the development of the Hopewell community?

4. How did national events affect Brooke and his employees?

5. Because Clement Brooke was part-owner as well as ironmaster at Hopewell Furnace, he was actively involved in both managing the day-to-day work of the furnace and making policy decisions about such things as investing in new land. Do you think combining these two roles would help the success of the furnace? Why or why not?

Reading 2 was adapted from the National Park Service's handbook, Hopewell Furnace: A Guide to Hopewell Furnace National Historic Site, Pennsylvania (Washington, D.C.: Division of Publications, National Park Service, Handbook 124, 1983).

Determining the Facts

Reading 3: The Hopewell Village Community

For more than 100 years, from the late 18th to the late 19th century, Hopewell Furnace was the center of a self-contained rural society of 200-300 people, all of whose work was directly or indirectly related to the production of iron. Many of these people lived in tenant houses furnished by the company. Much of their food was grown on acreage belonging to the company. They bought everything they couldn't grow or make themselves from the company story or itinerant peddlers. The heart of the community was the glowing furnace, whose cycles of filling and tapping set the pace of life.

A clear-cut paternalistic hierarchy of relationships characterized village society. The daily lives of the workers varied with the work they performed; their skills and responsibilities determined their social positions. During his term as ironmaster, Clement Brooke sat at the top of the economic and social pyramid, sharing profits and power only with his absentee partners. From his comfortable home overlooking the entire furnace community, the ironmaster made policy decisions, assumed responsibility for the successful operation of the enterprise, and largely controlled the lives of the furnace employees and their families. The ironmaster's mansion was at once family home, business headquarters, boarding house, and social center. The ironmaster and his family lived in the fashionable style of country gentry, wearing fine clothing and enjoying expensive furniture and other luxuries. A large staff of household servants, drawn largely from the wives and daughters of furnace workers, worked at the "Big House."

The furnace clerk was second only to the ironmaster in importance. He kept the books, acted as paymaster, and placated unhappy customers. He also managed the company store, ordering supplies for the village and charging workers' purchases against their wages. He was trusted with setting priorities for filling orders and could extend credit. The clerk also managed the furnace in the ironmaster's absence. Besides his considerable salary, the clerk was provided with room and board and travel expenses. The holders of this prestigious job often lived in the home of the ironmaster, a position that an enterprising clerk might well expect to attain in time.

Below the management level, the most important man in the community was the founder, the person responsible for the efficient operation of the furnace. He had immediate oversight of the iron workers and was accountable for the quality of their products. Because of his important position, he and his family held considerable prestige in the community.

The majority of other Hopewell Furnace workers labored in 12-hour shifts at grimy, often dangerous tasks. The noisy, reeking, fiery hot furnace defined their work. Skilled craftsmen such as moulders and colliers enjoyed higher earnings and greater prestige than ordinary furnace workers or ancillary workers such as woodcutters, miners, teamsters, and household servants. Moulders, the elite of the furnace workforce, received higher rates than the founder. Fillers and guttermen had the most dangerous jobs and received less pay than the skilled workmen. Blacksmiths, mill and wheelwrights, and other skilled artisans provided indirect, but essential services to the furnace. Farmers and farm workers developed the arable land of the village and grew much of its food.

Many women found paid employment at Hopewell, although few appear in the furnace records. Some skilled women earned wages as seamstresses, cooks, and candle makers for the Big House. Others added to the family income by boarding single men, selling eggs and chickens, marketing home-baked or home-preserved products, and sewing, repairing, or laundering clothing. Many women and children helped with farm work at harvest time. Children were apprenticed at early ages or went to work to help support their families.

Some African Americans were also employed at Hopewell and received equal pay with white workers for the same jobs. They were, however, most often working at the less skilled jobs. Neither living quarters nor social activities were segregated. The forests of southeastern Pennsylvania were known as a shelter for runaway slaves. Because many black workers appear on the records of Hopewell Furnace for only short periods of time, and because there is some evidence that Clement Brooke was an abolitionist, it is possible he provided runaway slaves with jobs until they could move on to safer areas further north.

While a class system did exist within the workplace, there was also a strong sense of community in Hopewell. Only the ironmaster and his family were really set apart. Everyone else found that their social lives ebbed and flowed with the rhythms of the furnace. When a long blast ended, the people celebrated their temporary freedom from its demands. They held "entertainments," went fishing or hunting, skating or sleighing. At special times, Election Day or the Fourth of July, civic duties were combined with social drinking. Workers and their families often danced, and sometimes fought, the night away. For Hopewell workers, life was a mixture of much hard work and some play.

Questions for Reading 3

1. Compare the duties of owner, ironmaster, clerk, and founder. If you had to choose, which of these jobs would you prefer? Why?

2. Which furnace workers were considered the most important and were paid the most?

3. Which jobs were the most dangerous? Why? How well were these jobs paid? Why do you think that was so?

4. What paid work did women and children perform? What unpaid work do you think they provided? How important do you think this unpaid work was to the community?

5. The reading suggests that there was a degree of equality at Hopewell Furnace. How would you compare that "equality" with today's definition?

Reading 3 was was adapted from the National Park Service's visitor's guide to Hopewell Furnace National Historic Site and the handbook, Hopewell Furnace: A Guide to Hopewell Furnace National Historic Site, Pennsylvania (Washington, D.C.: Division of Publications, National Park Service, Handbook 124, 1983).

Visual Evidence

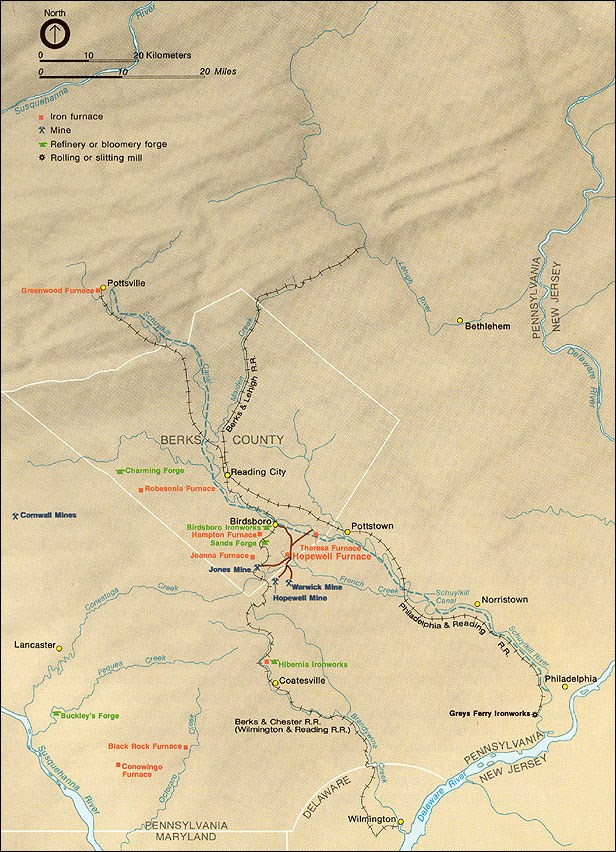

Illustration 1: 19th-century blast furnace in operation.

(National Park Service, Richard Schlecht, illustrator)

Questions for Illustration 1

1. Based on the readings and Illustration 1, describe how a blast furnace operated.

2. What jobs are being performed by the men in the illustration?

3. What was the purpose of the blowing tubs? How were they powered?

4. Molten iron can reach a temperature of 3000 degrees Fahrenheit. What protective clothing do the workers shown in this illustration wear? What other protection would you want if you were working at a furnace?

Visual Evidence

Photo 1: "Jumping the Pit," Hopewell Furnace, 1936.

(National Park Service, Jackson Kemper, photographer)

Charcoal pits, measuring 30 to 40 feet in diameter, were generally located in cleared areas, often near where the wood had been cut. Four-foot lengths of wood were stacked on end around a wooden chimney in the center of the pit. It took about 25 to 50 cords for each pit (a cord is a stack of four-foot logs measuring eight feet long by four feet high). The mound was then covered with leaves and dirt and set on fire at the center. A collier carefully tended the smoldering wood 24 hours a day for 10 to 14 days until it had "come to foot" or was completely charred. The temperature of the interior of a charcoal pit was generally from 700-800 degrees Fahrenheit, with some parts reaching more than 2000 degrees. During the coaling, the master collier and his helpers lived in primitive huts near the pits.

This photo shows Lafayette Houck, the last of the Hopewell colliers, on the first day of a 1936 demonstration of charcoal-making at Hopewell Furnace. Mr. Houck is walking on the burning pile to find soft spots, which had to be dug out and filled in to maintain even burning.

Questions for Photo 1

1. What were some of the challenges associated with being a collier?

2. During the 1830s, the furnace paid approximately 20 colliers, each tending eight or nine pits. In most years additional wood for charcoal had to be bought from outside suppliers. What inferences can you make about the appearance of the landscape around the furnace?

3. A good woodcutter could cut about two cords a day. How many days did a woodcutter need to work to provide enough wood for a charcoal pit?

Visual Evidence

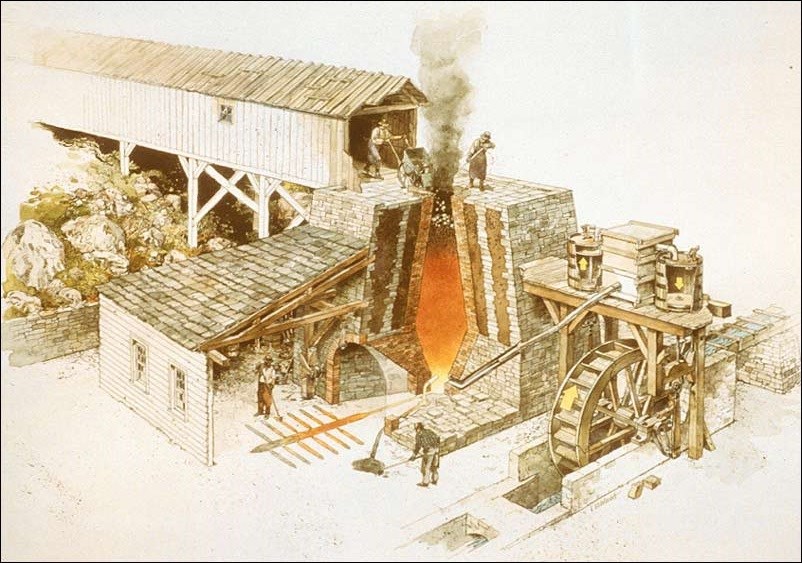

Illustration 2: Artist's view of Hopewell Furnace National Historic Site in the 1950s.

(National Park Service, J. Kenneth Townsend, illustrator)

In the 1950s, the National Park Service restored the surviving buildings on the site to represent Hopewell Furnace during the period from 1820-1840. This view shows the restored historic site.

Key to Illustration 2

1. Roads used to carry raw materials to the furnace and finished products to market

2. 1853 anthracite furnace that was meant to modernize Hopewell's operations. The experiment failed

3. Recreated charcoal hearth

4. Charcoal house, which could hold 90,000 bushels, and the shed where the charcoal was cooled

5. Furnace bank, connecting shed, and bridge house, where charcoal, limestone, and ore were carried to the furnace

6. Water wheel that drove the blast machinery

7. Hopewell store

8. Cast house

9. Furnace

10. Shed where castings were cleaned before shipment

11. Blacksmith shop

12. Ruins of a schoolhouse built by the company in 1837

13. Tenant houses

14. Barn, accommodating 36 horses or mules

15. Spring house for perishable foods

16. Smoke house and bake oven

17. Ironmaster's mansion or "Big House." Built in three stages, the house had 19 rooms on four floors

18. East headrace that carried water from a nearby creek to the water wheel

Questions for Illustration 2

1. Locate the ironmaster's mansion and the tenant houses. Why do you think the ironmaster and the workers lived so close to the furnace? What do you think it might have been like to live so close to the furnace?

2. How is the drawing different from or similar to what you imagined the site would look like based on the readings?

3. This drawing represents the appearance of the restored Hopewell Furnace Historic Site. How would it differ from a drawing showing the village when the furnace was in operation? What do you think it would have been like to live there then?

Visual Evidence

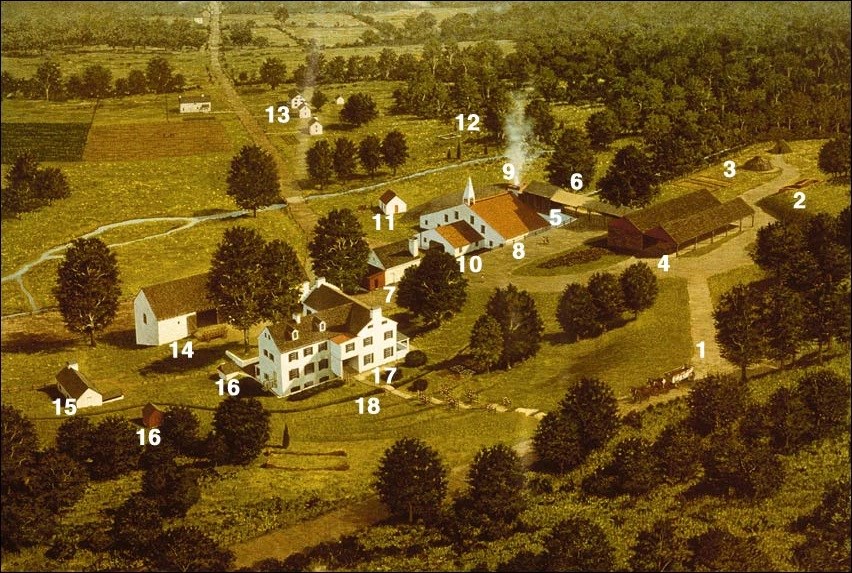

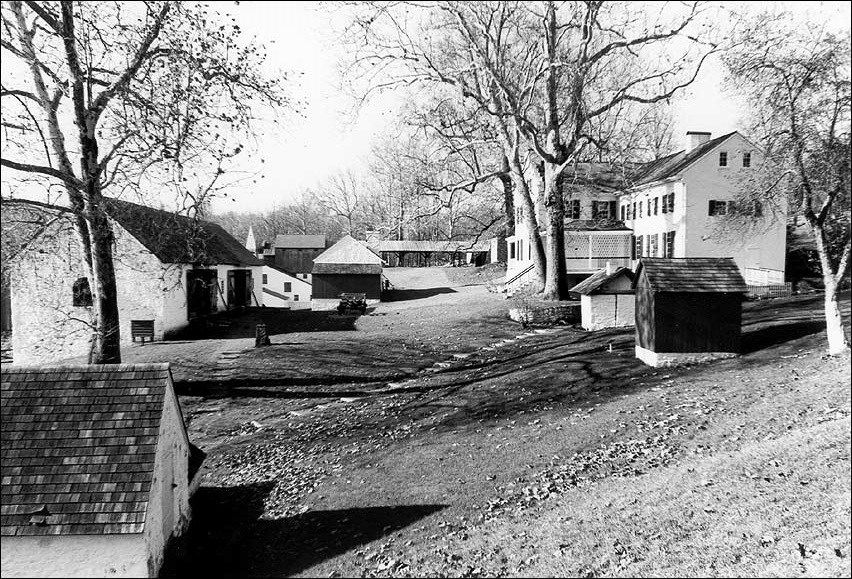

Photo 2: Ironmaster's House and Outbuildings.

(National Park Service, Joseph Lee Boyle, photographer)

(National Park Service, Joseph Lee Boyle, photographer)

Photo 3 shows three tenant houses (Number 13 on Illustration 2). The one on the left is a two-family house.

Questions for Photos 2 and 3

1. Compare the view of the Big House in Photo 2 with the view in Illustration 2. What differences can you find? Which gives you a better idea of the size of the house?

2. Examine Photo 3. In 1855, there were 14 tenant houses renting for $12 to $25 per year. Rent was deducted from the workers' pay. How do you think that might have affected relations between workers and owners?

3. Do the illustrations or the photographs give you a better understanding of the site? Explain your answer.

Visual Evidence

Photo 4: Typical Hopewell Furnace Products.

(National Park Service, George Fistrovitch, photographer)

Questions for Photo 4

1. This photo shows Hopewell products dating from the 1770s through the 1880s. Examine it carefully. How many of these products can you identify? How would they have been used? How many of them are still used today?

2. Look at the four Hopewell stoves shown in the photo. These stoves were used for both heating and cooking, replacing fireplaces in many rooms of prosperous houses. Why do you think there were so many different sizes and styles? Why do you think they were so highly ornamented?

Putting It All Together

The work performed at Hopewell Furnace was interdependent; each man and woman depended on other workers to make his or her own job possible. Farmers, teamsters, woodcutters, and homemakers were as essential as the ironmaster, the founder, moulders, and guttermen. The following activities are designed to help students illustrate their understanding of this fact.

Activity 1: Working at Hopewell

Divide students into three groups: (1) furnace work (creating iron products), (2) forest work (making and delivering charcoal), and (3) field work (growing crops, caring for livestock). Have each group use lesson materials to make a list of all the jobs in their category they have read about, and have them make assumptions about jobs not described.

On the chalkboard draw three large circles, labeling each as furnace, forest, or field. As each group reports its list, write the occupations in the appropriate circles. Ask students how particular workers could be identified as "links" to the other groups (e.g., teamster, collier, clerk). Use arrows to show ties between groups. Ask what would happen if anyone neglected to do his or her assigned work. Ask if one set of jobs is more important than the others. If they cannot decide on an answer to that question, the point of interdependence is clear.

Then ask students to research a local industry or business to find out if workers there are as interdependent as those at Hopewell and explain why or why not. You may be able to have the owner or manager of a local firm speak to the class about the interdependence involved in that business. Many such people are happy to provide students with copies of their managerial flow charts.

Activity 2: Economic History in the Local Community

Ask students to research the economic history of their own state and local community to find out how it resembled or differed from colonial Pennsylvania and Hopewell. Some questions students might investigate include:

l. Hopewell is an example of a "company town," that is, a town built by a single company that dominated all aspects of life in the community. Were such communities part of the economic history of your state?

2. Iron-making is considered a "heavy industry," which is defined as an industry producing or refining basic materials used in manufacturing. Are there, or were there, heavy industries in your community or nearby? What happened to them?

a. Was one heavy industry replaced by another heavy industry? Why did this happen?

b. Has all heavy industry died out in your area? If so, why?

c. Has the disappearance of any local industry caused widespread unemployment? How has your community responded?

3. If your community or the nearby area has never had heavy industry, determine why not. What is the community's economic base today? Is it stable? Ask students to present their findings in a written or oral report.

Hopewell Furnace: A Pennsylvania Iron-making Plantation--

Supplementary Resources

By looking at Hopewell Furnace: A Pennsylvania Iron-Making Plantation, students explore how Hopewell functioned as a productive work unit and how work defined social relationships in this early National period community. Those interested in learning more will find that the Internet offers a variety of interesting materials.

Hopewell Furnace National Historic Site

Hopewell Furnace National Historic Site is a unit of the National Park System. Visit the park's web page to learn more about the park's history and visiting the site.

Pennsylvania Historical and Museum Commission

The Commission website contains information on the role of the iron and steel industry in the history of the state and on Cornwall Furnace and the Scranton Iron Furnaces, historic sites administered by the Commission.

Library of Congress

Search the Library of Congress's American Memory web page for primary resources on iron making and early National period America.

The Historic American Buildings Survey/Historic American Engineering Record Collection

The Historic American Buildings Survey/Historic American Engineering Record Collection contains information, photographs, and drawings of historic iron making furnaces and other related installations across the country.

For Further Reading

Students and educators wishing to learn more about Hopewell Furnace and the Hopewell Furnace community may want to read: Hopewell Furnace: A Guide to Hopewell Furnace National Historic Site, Pennsylvania (Washington, D.C.: Division of Publications, National Park Service, Handbook 124, 1983) or Joseph E. Walker, Hopewell Village: A Social and Economic History of an Iron Making Community (Philadelphia, PA: University of Pennsylvania Press, 1966).